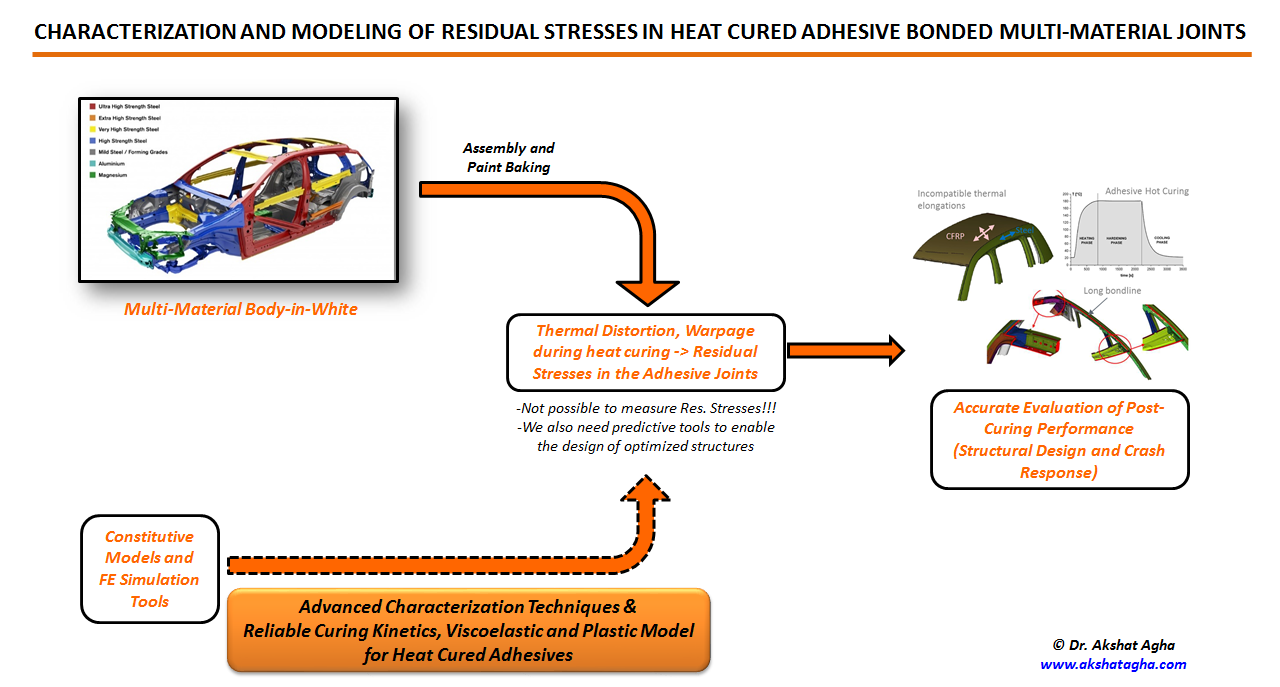

Curing Induced Residual Stresses in Adhesive Joints

Automotive-grade structural adhesives are heat-cured epoxy-based thermosets. The heat curing process poses a critical problem pertaining to the differences in the coefficient of thermal expansion (CTE) of the joined materials; the mismatch of which has significant implications on the integrity and response of the BIW to external loading (mainly thermal).

One of the main challenges in the joining of multi-material components is the assessment of the nature and magnitude of the residual stresses developing in the adhesive bond during the heat curing manufacturing process. Numerical modeling of these residual stresses can provide insights for making informed decisions related to (i) material substrate properties; (ii) adhesive properties i.e. low, medium, or high stiffness; (iii) bondline geometry i.e. bondline width and bead thickness; (iv) curing cycle characteristics; and (v) fixation design i.e. type, spacing, the number of joints and much more.

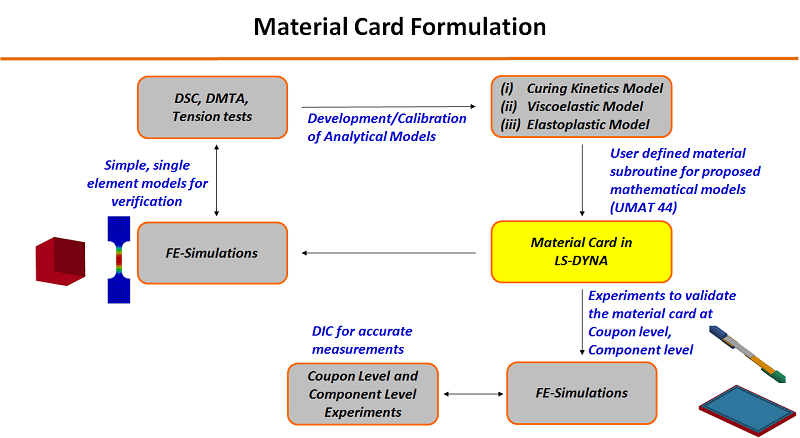

There is a need for reliable experimental techqniques and robust mathematical models to comprehensively capture the effects of CTE mismatch in adhesive bonded joints.